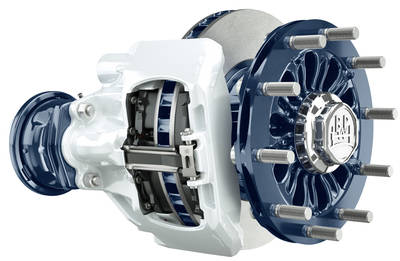

The BPW ECO Disc TS2 is a lighter, more robust, more economical version of the million seller

|

The BPW ECO Disc is a success story. Since its launch in 2009, two million have been sold and in 2016 it was already the most-used trailer disc brake in Europe. It allows the brake disc to be changed without dismantling the caliper, saving up to three hours in the garage. The next generation, the TS2, is even better at limiting emissions and operating costs – as well as being easy to service, it’s 4 kg lighter and more compact, yet even more robust.

Put the brakes on costs with the Brake Pad Monitor and BPW TireMonitor

The wrong tyre pressure increases tyre wear and fuel consumption dramatically. This is why the BPW TireMonitor tyre pressure sensor quickly pays for itself. At a mileage of 120,000 kilometres per year, the vehicles consume an average of 800 litres less fuel and reduce their CO2 emissions correspondingly by over 2,100 kg. The BPW Brake Pad Monitor also increases road safety and reduces operating costs. The tyre pressure and brake pad wear sensor communicate via app with the driver and online with the Cargofleet 3 open telematics platform from BPW subsidiary idem telematics, ensuring maximum transparency.

Tackling a major cause of lorry accidents with the iGurt

The German insurance industry association GDV estimates that 70% of loads transported in Germany are secured insufficiently or not at all. This issue causes 20-25% of lorry accidents. And it’s not just tipped trailers and lost loads that cause major damage – a mid-sized haulier with 160 trailers records an average of 15,000 cases of damage per year due to poorly-secured loads alone. The iGurt is an innovative smart strap monitoring system. It is attached to the lashing strap and measures tension and monitors it throughout the journey. The driver can see on a smartphone app whether the strap is in place and receives an alert if it becomes loose. This is how the iGurt prevents accidents and load damage. It also permits extensive documentation, such as for vehicle connections and driver changes, and therefore makes an additional contribution to transport safety.

The eTransport electric drive axle breathes new life into 7.5-tonne transport vehicles

|

In early 2019, the electric drive axle will enter small-scale production, with Paul Nutzfahrzeuge, Europe’s leading specialist in special vehicles and commercial vehicle conversions beginning to retrofit its diesel-powered 7.5-tonne transporters. They are based on the Mercedes-Benz Vario, which is very popular, especially in local municipalities. In line with the slogan ‘diesel out, e-axle in’, the conversion takes only two weeks and gives the sometimes very complex and expensive special municipal vehicles an emission-free second life. In summer, the city of Wiehl acquired the first refitted vehicle, and together with the global logistics service provider Hellmann Worldwide Logistics and Logwin-Logistics, BPW began a six-month field test phase examining the use of e-mobility in commercial goods vehicles. BPW uses lithium-ion systems with a nickel-manganese-cobalt base for the batteries, by far the most advanced cellular chemistry currently on the market. With the electric axle drive, however, it isn’t only possible to reduce harmful emissions. It also makes entirely new vehicle configurations possible – instead of sitting high above the diesel as they always have done, in future, drivers can sit at eye level with pedestrians and cyclists and see them better, reducing the number turning accidents with cyclists that often have fatal consequences.

BPW is also currently developing a scalable electric drive concept for commercial vehicles with a total weight of up to 26 tonnes, which was presented for the first time at the IAA 2018.

The BPW CargoTracer makes phoning up about your delivery a thing of the past

|

Delays in delivery can throw off sensitive digitally controlled production processes. That’s why senders and recipients still spend a great deal of time phoning up to find out about their deliveries. The new BPW CargoTracer is an innovation that makes digital tracking affordable for the first time – the palm-sized device works using ultra narrowband wireless technology and the battery lasts up to two years. The CargoTracer transmits its position data to a cloud platform that can be integrated into digital logistics processes and ERP systems such as SAP. It therefore allows goods carriers, containers and other precious operating resources to be tracked, managed and protected against loss.

Digital seal: the invisible, lead-free seal for the cargo hold

In transport, vehicles' rear frames, which conceal precious cargo, are often secured using seals containing lead. Instead of cumbersome physical seals, BPW subsidiary idem telematics is now offering a hi-tech alternative – the digital seal. It permanently monitors whether the rear door has been opened without authorisation during transport. Every unauthorised opening is detected and saved. Just like when a seal is broken, this process cannot be reversed. Thanks to this solution, responsibility for the load and the respective transfer of risk for trailers and swap bodies are documented in a manner that can be used in a court of law. This eliminates time-consuming manual sealing and there is no visible seal to indicate that the cargo is valuable.

Tackling microplastics

Remains of burst tyres or splintered plastic parts are part of the big picture on Europe’s highways. All together, a massive mountain of plastic and rubber remains piles up. These don’t just litter the hard shoulder. They are also quickly broken down into what are known as microplastics, whose risks have only just recently been discovered. Microplastics travel through bodies of water into the food chain and can cause lasting damage to humans and animals.

The BPW Group is working actively to combat microplastics, such as with the BPW TireMonitor tyre pressure monitoring system, which prevents tyres from bursting and also reduces vehicles’ fuel consumption and emissions in turn.

In Greenflex, the Danish BPW subsidiary HBN-Teknik has also developed a thermoplastic mudguard which is particularly shock-resistant and resistant to friction, oil and weather conditions. This helps to reduce the amount of microplastics produced in the long term. The mudguards are made of 100% recycled polypropylene and a polyethylene-reinforced special rubber mix – a strong combination that ensures that the mudguards retain their form at temperatures up to 80 degrees Celsius and remain shock- and impact-resistant at temperatures of up to minus 30 degrees Celsius.

The Ermax brand trailer tail lights have also been rethought – traditional housings have been afflicted massively by potholes, vibrations, extreme temperatures and parking jostling, so they usually only last for an average of a year and ultimately end up as colourful scraps on the hard shoulder and in the water supply. The new, ultra-robust polycarbonate Ermax TM10 LED tail light is 17 times as resilient as traditional lights – not only reducing costs, but also easing the burden on the environment.