Beyond Efficiency

All BPW Group products and solutions are systematically designed for maximum efficiency in transport and logistics. What benefits BPW’s customers economically also reduces the burden on people and the environment – year after year, BPW and its subsidiaries make significant progress in reducing consumption, wear, downtimes, congestion, detours, noise and exhaust emissions and the number of empty runs.

However, at BPW, the understanding of product responsibility goes far beyond merely meeting efficiency criteria, and instead covers the entire life cycle – from obtaining raw materials, manufacture, delivery and use through to recycling and disposal.

An unparalleled environmental, safety and quality culture

In January 2018, BPW was recertified in accordance with ISO 9001:2015 and IATF 16949:2016 and therefore fulfils the highest standards of quality in the automotive industry with respect to product, process and service quality. Certification confirms that the company fulfils comprehensive requirements with regard to risk management, compliance, environmental protection, energy use and occupational safety, among others. Beyond commercial vehicle industry standards, the IATF standard itself is the highest level in the automotive industry. Prior to certification, BPW comprehensively refined its quality management and connected all of the company’s divisions in the aim of reorganising the entire system of processes. It’s not just the employees who benefited from this cross-department project, but the subsidiaries, too – that’s why the BPW Group specialist in composite material solutions, HBN-Teknik from Denmark, has also been certified in accordance with IATF 16949:2016 since June 2018.

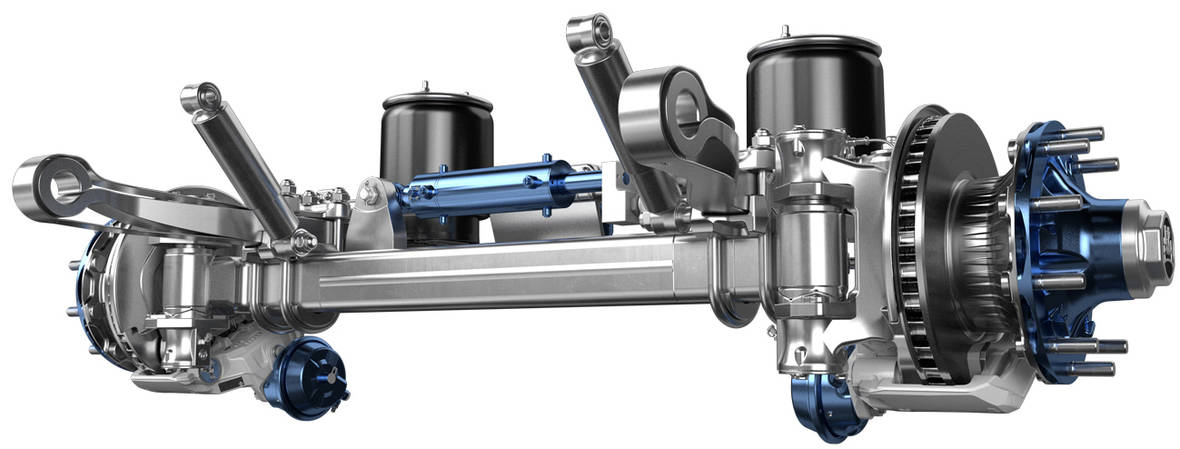

Steering you in the right direction – the self-steering axle saves tyres and fuel

With the LL self-steering axle, BPW has developed a unique steering stabiliser for trailers which works purely mechanically and, depending on load, improves manoeuvrability on corners and in turns. The exact steering and track behaviour, however, does not just increase the stability and security of the trailer – with a mileage of one million kilometres, the system saves up to 10,000 litres of fuel, thus reducing the vehicle’s CO2 emissions by over 26,000 kg. Over the same mileage, use of the self-steering axle also saves around 40 tyres per vehicle and protects the structure, frame and road.

|

The first plug-and-play additional steering for self-steering axles makes manoevring even safer

For drivers, reversing drawbar trailers in small spaces entails stress, lost time and a vastly increased risk of accidents. That’s why BPW is offering electro-hydraulic additional steering to assist reverse manoeuvring for its tried and tested self-steering axle from February 2019. The registration-free plug-and-play solution operates independently of the tractor unit. This is because innovative sensors and smart control technology detect and control the direction and steering angle fully automatically. This is the first time BPW has made a significant increase in safety easily available to all transport companies.

Travelling light: lightweight components for extra capacity

Virtually every department was involved in the recertification project, throughout all development, production and customer processes. I have never had such an intense ‘all-hands-on-deck’ experience in the company. This project has enhanced BPW’s understanding of the customer and quality by leaps and bounds.

Dr Michael Metzele, Head of Quality and Customer Service

In transport, every excess kilogram causes harmful emissions and costs the haulier fuel and usable load. This is clear from the success of BPW’s modular Airlight II air suspension system, the lightest running gear available on the market. For tank and silo vehicles, BPW will offer maximum weight savings with lightweight construction – with special components such as the light tube trailing arm (a reduction of 16 kg) and the BPW aluminium hub (a reduction of 18 kg), BPW achieves a module weight of just 370 kg. The additional weight of around 200 kg for emission control systems (Euro 6 standard) can be compensated for by nearly 100 kg thanks to the extremely light Airlight II running gear with lightweight components.